Download area

Download a tutorial

Download Non Equilibrium software package

Modelling Activity

Non Equilibrium thermodynamics for Glassy Polymers

CFD modeling of fluid transport in solid materials

Non Equilibrium thermodynamics for Glassy Polymers

Introduction

Assumptions and conclusions

Solubility calculation

Model parameters

Some results

References

Introduction: fluid sorption in glassy polymers

Glassy polymers are non equilibrium systems which cannot be described

with conventional equilibrium models and they have higher specific volume

than the equilibrium value.

For the gas sorption in glassy polymers, that is relevant in many applications

as in the membrane separation field, an empricial equation is often used

that relates the amount of fluid abosrbed to the gas phase pressure (or

fugacity), the dual-mode model (1)

![]()

Although this model has been used successfully and extensively over the

years to represent the typical convex shape of solubility isotherms of

glassy polymers, its physical assumptions present an oversimplified picture

of the physico-chemical factors affecting the sorption process. The three

model parameters, kD, C'H

and b, which are obtained by curve-fitting the model to experimental

data, can only be used in the range of temperature and pressure over which

the regression is performed and for the specific penetrant-polymer pair

for which the experimental sorption data were obtained. In this regard,

an extensive study of the dependence of the dual-mode parameters on the

pressure range used for the fitting procedure was presented by Bondar

et al. (2)

These observations imply that this model cannot be used for predictive

purposes. Moreover, the basic physical interpretation of the dual

mode equation cannot be used, even qualitatively, to describe the behavior

of polymer-penetrant pairs, such as alcohols and glassy PTMSP, which exhibit

an S-shaped sorption isotherm. (3)

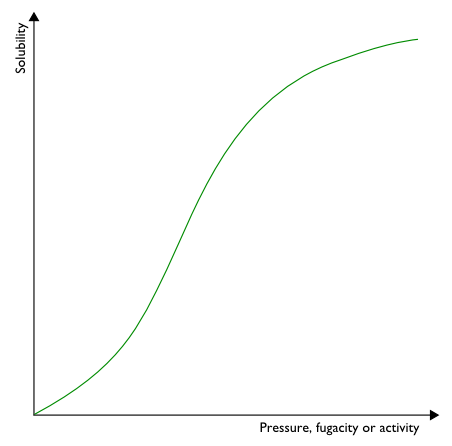

Sigmoidal sorption isotherm

(e.g. alcohols in PTMSP)

Sigmoidal sorption isotherm

(e.g. alcohols in PTMSP)

Alternative models have been developed to describe gas solubility in

glassy polymers; these models are generally constructed on a more fundamental

basis than that of the dual mode model. (4-6)

The non-equilibrium lattice fluid (NELF) model, proposed by Doghieri

and Sarti, (7-9) considers a single population of penetrant molecules

dissolved into the glassy polymer. This model can be used in a predictive

way, based only on pure component parameters, and has proven to be

quite satisfactory for all the gas-polymer pairs examined so far. The

glassy state of a polymer is a non-equilibrium phase in which the

Gibbs free energy does not correspond to the minimum attainable value.

The NELF model relies on the hypothesis that the Gibbs free energy of

a glassy polymer can be described by considering the density of the

polymer to be an internal state variable. The NELF model adopts from

the equilibrium Gibbs free energy expression for polymer mixtures proposed

for the lattice fluid theory by Sanchez and Lacombe.(10-11) The

gas solubility is calculated from the phase equilibrium condition, which

requires equality between the chemical potential of the penetrant species

in the glassy polymer and in the external gaseous phase.

The NELF model was then generalized in order to account for more recent

and accurate Equation of State Models giving rise to the so called NET

GP approach (Non Equilibrium thermodynamics for Glassy Polymers) which

is interfaced to Perturbedh Hard Sphere Chain (PHSC) and Statistical Associating

Fluid Theory (SAFT) Equations of State.

The glassy polymeric phase is

i) homogeneous ii) isotropic iii) amorphous

The glassy phase reaches an asymptotic pseudo equilibrium condition

According to these assumptions it can be demonstrated that:

the non-equilibrium Helmholtz free energy,in a general non-equilibrium

state coincides with the corresponding property evaluated on the equilibrium

curve at the same T, p, and composition:

![]()

Similarly, the chemical potential per unit mass of solute i in the glassy

phase is given by:

![]()

Therefore, once an expression for aEQ is selected for the polymer-penetrant

mixture, the corresponding non-equilibrium equation is readily obtained

. Such results are derived in general terms and are independent of the

particular EoS model used for the free energy

Non-equilibrium free energy functions are given by different Equations

of State (EoS) models as :

Lattice Fluid (LF),(10-11)

Statistical Associating Fluid Theory (SAFT) and PC-SAFT,(12-15)

Perturbed Hard Sphere Chain (PHSC) model (16-18 )

and give rise to the corresponding non-equilibrium models indicated as

NELF, NE-SAFT and NE-PHSC, respectively. The non-equilibrium

information is represented by the value of pol, which must be measured

experimentally and cannot be calculated from the equilibrium EoS.

Solubility calculation

In the case of true thermodynamic phase equilibrium, solubility is evaluated

by equating the equilibrium chemical potential of the j-th penetrant in

the polymeric solid to that in the external fluid phase, using also the

equilibrium value of the polymer density given by the equation of state

at that T, p and composition.

![]()

In the pseudo-equilibrium state of a glassy polymer, the relaxation of

polymeric density with time is kinetically hindered; its value becomes

asymptotically constant in time, even though it is not equal to the true

equilibrium value. Under these conditions, the time rate of change of

rho becomes negligibly small, though not exactly equal to zero, while

the equation representing true thermodynamic equilibrium (minimization

of Gibbs free energy)is not obeyed.

The polymer density value during sorption is normally not available at

all penetrant activities and that is a constraint for the application

of the NET-GP approach as a completely predictive tool. In several cases

of practical interest, such as at low activity, or for solutes with very

low solubility, the density of the pure glass provides a very good estimate

of the actual polymer density and the NET-GP approach can be applied in

a predictive way.

When swelling agents or higher gas pressures are used, the NET-GP approach

needs some further consideration. In particular, for the gaseous phases

it can be noticed that, generally, the polymer density during sorption

varies linearly with penetrant pressure:(19)

|

|

| Variation of polymer density with pressure during gas sorption in different polycarbonates | NELF model prediction of the corresponding solubility isotherms (20) |

where the swelling coefficient, ksw, represents the effect of gas pressure

on glassy polymer density and is a non-equilibrium parameter, depending

on thermomechanical and sorption history of the sample. The value of the

swelling coefficient, ksw, can be obtained, in principle from a single

experimental solubility datum at high pressure for the system under consideration.

(20)

Model parameters

The pure component parameters for the EoS model chosen are obtained by

fitting the EoS calculations to pure component equilibrium data. For the

penetrant, volumetric and/or vapour pressure values are frequently available

and can be used to that aim. For the polymer, one can use volumetric data

as a function of temperature and pressure above the glass transition temperature,

frequently available in the open literature and in some compilations,

(21) in the common case in which the rubbery phase can be reached before

thermal degradation. An example of such procedure is shown in Figure ,

where volumetric data above and below Tg are given for polycarbonate and

the SAFT model is used to fit the data above Tg, the resulting parameters

for the SAFT model are s: =3.043 Å, M/m=25.00

g/mol, u0/k=371 K. (22) The pure component

parameters can also be predicted using experimental PVT dtaa simulated

with molecular dynamics (MD) simulations.(23)

|

|

| Fitting of SAFT EoS parameters on experimental PVT data for polycarbonate (22) | Fitting of PC SAFT EoS parameters on MD simulated PVT data for Kapton (23) |

All mixture models for free energy have also one binary interaction parameter, kij, associated to each couple of chemical species, which can be obtained separately, e.g. from gas-polymer equilibrium data in the rubbery phase, when available. In the absence of any direct experimental information, the first order approximation can be used for kij or, alternatively, it can be treated as adjustable parameter as is often done in the thermodynamic studies of liquid-vapor equilibria. For mixtures formed by components of similar chemical structure, the value of kij is essentially equal to 0.0 (regular solution behavior). .

|

|

| Prediction of the solubility of n-C6 in Polystyrene below the glass transition (NELF model) and above the glass transition (LF EoS). (23) | Water vapor and liquid solubility in polycarbonate: experimental data and NELF model (24) |

(1) R. M. Barrer, J. A. Barrie, and J. Slater, J. Polym. Sci., 27, 177

(1958)).

(2) V. I. Bondar, Y. Kamiya, and Y. P. Yampol'skii, J. Polym. Sci.: Part

B : Polym. Phys., 34, 369 (1996)) .

(3) F. Doghieri, D. Biavati, and G. C. Sarti, Ind. Eng. Chem. Res., 35,

2420-2430 (1996)).

(4) T. Oishi and J. M. Prausnitz, Ind. Eng. Chem. Proc., Des. Dev., 17,

333 (1978);

(5) R. M. Conforti, T. A. Barbari, P. Vimalchand, and M. D. Donohue, Macromolecules,

24, 3388-3394 (1991);

(6) R. G. Wissinger and M. E. Paulaitis, Ind. Eng. Chem. Res., 30, 842-851

(1991)).

(7) F. Doghieri and G. C. Sarti, Macromolecules, 29, 7885-7896, (1996);

(8) G. C. Sarti and F. Doghieri, Chem. Eng. Sci., 53, 3435-3447, (1998);

(9) F. Doghieri and G. C. Sarti, J. Membr. Sci., 147, 73-86, (1998)

(10) R. H. Lacombe and I. C. Sanchez, J. Phys. Chem., 80, 2568-2580 (1976);

(11) I. C. Sanchez and R. H. Lacombe, J. Polym. Sci.: Polym. Letts. Ed.,

15, 71-75, (1977).

(12) Huang SH, Radosz M. 1990. Ind. Eng. Chem. Res. 29:2284-94

(13) Chapman WG, Gubbins KE, Jackson G, Radosz M. 1989. SAFT. Fluid Phase

Equilib. 52:31-8

(14) Chapman WG, Gubbins KE, Jackson G, Radosz M. 1990. 29:1709-21

(15) Gross, J.; Sadowski, G. Ind. Eng. Chem. Res. 2001, 40, 1244.

(16) Song Y, Hino T, Lambert SM, Prausnitz JM. 1996. 117:69-76

(17) Hino T, Prausnitz JM. 1997. Fluid Phase Equilib. 138:105-130

(18) Song Y, Lambert SM, Prausnitz JM. 1994. Macromolecules. 27:441-48

(19) Wissinger G, Paulaitis ME. 1987. J. Polym. Sci, Part B: Polym. Phys.

25:2497-510.

(20) Giacinti Baschetti M, Doghieri F, Sarti GC. 2001. Ind. Eng. Chem.

Res. 40:3027-37.

(21) Zoller P, Walsh D. 1995. Standard Pressure-Volume-Temperature Data

for Polymers. Lancaster: Technomic

(22) M.G. De Angelis, G.C. Sarti, Annu Rev Chem Biomolec Eng, 2011, 2,

97 - 120

(23) M. Minelli, M.G. De Angelis, D. Hofmann, Fluid Phase Equilibria 2012,

333, 87 - 96

(24) M.G.

De Angelis, G.C. Sarti, AIChE Journal, 2012, 58, 292-301.